滨苍听听first ski trailer for its 2012听,听听is on a boat, one in Antarctica, skiing sick lines, singing and dancing and raising the roof.听

He鈥檚 probably crooning so contentedly because he is in one of the most beautiful and hard to reach places in the world shredding pristine slopes and being ridiculous for the camera.

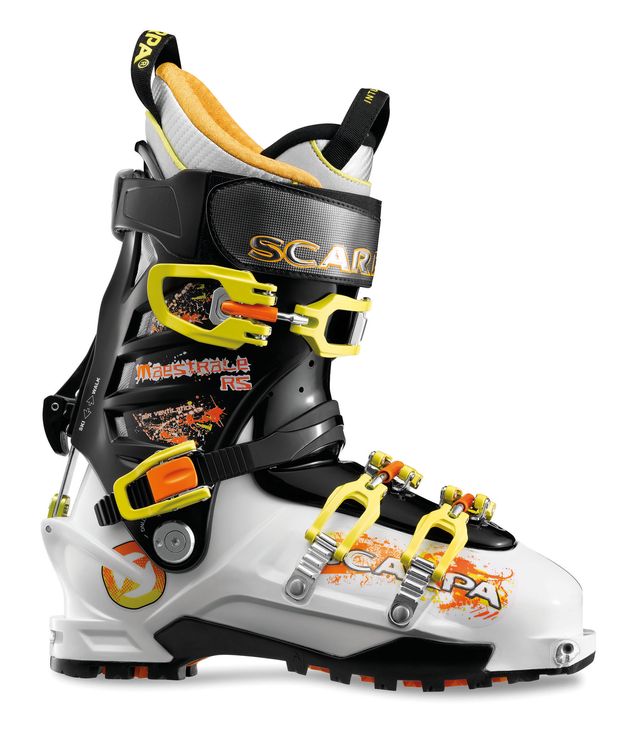

Another reason he might look

so smug is that he just signed a deal with , a leading Italian footwear brand. And he鈥檚 not just going to be one of Scarpa's athletes. Along

with serving as a Scarpa ambassador and testing new Scarpa products, Davenport

will be a key member of the product development team for a new line of Scarpa

freeride boots coming out in time for the 2013/14 season.

Davenport is one

of the most accomplished big-mountain skiers in the world. “I鈥檓 a product guy,

a gear geek if you will. I love equipment, I love tweaking it, and I believe

that you can always make a better product,” he said. “There鈥檚 very definitely

an opportunity in the freeride category鈥攁 product for a specific set of needs

that doesn鈥檛 yet exist in the marketplace. I鈥檓 joining Scarpa to be involved in

the development of the strongest boot line yet, specifically built for the

needs of freeride and sidecountry skiers.”

In a world where

most footwear companies are owned by a big conglomerate, Scarpa is unique. It鈥檚

still privately owned by the Parisotto family. Three Parisotto brothers created the

company and now their children own and operate it.听The family is on-site at the factory every day, including the Parisotto patriarchs, Luigi, Francesco, and Antonio鈥攏ow all in their 80s. In fact, many of the people who work in the factory are second- or third-generation craftsmen and women. They make footwear with the care of artists carving masterpieces.

Scarpa is a clear leader in footwear and ski boot innovation. The company was the first to make a plastic telemark ski boot, and the first to make a waterproof breathable hiking boot. Scarpa still manufactures all of its high-end injection-molded ski boots in Italy as well as its climbing and mountaineering shoes and boots. I had a chance to visit the company headquarters this

summer, and was blown away by the time, skill and labor that goes into

each pair of Scarpa shoes. Not only is each piece of a Scarpa Italian-made shoe or boot cut, stitched and glued by a skilled craftsman, but the boots are laced by hand, the paper is placed in the toe of each shoe by hand to help it maintain its shape, and each pair of shoes is placed in the box by a human, not a machine. I had no idea; I will never look at my shoes the same way.

“We鈥檙e all

product people. We love having the right product, the best thing out there, the

most high performance thing we can have,” Davenport said. “So I think that also

makes this a great match.”

鈥擝erne Broudy