Here is the good news: Expanded polystyrene (a.k.a. EPS, or the branded name Styrofoam) is recyclable. Here’s the bad news: much of it is not recycled and therefore EPS-based surfboards are made from virgin EPS. Some more bad news: Only about 30 percent of surfboards are made with EPS. One more piece of bad news: The most commonly used resins* used in surfboard manufacturing are toxic. , a non-profit aimed at helping the surf industry reduce its environmental impact, is hoping to change all of that bad news.

The NGO celebrated the launch of its , which finally established an industry benchmark that board makers can follow in order to boost the environmental credibility of their products, last week in San Francisco. “Ecoboard is the industry’s first third-party science-based benchmark,” Sustainable Surf’s co-founder Michael Stewart told me.

Stewart is a life-long surfer, and he looks like one. But he’s also all business, which becomes apparent as he starts to talk shop, rattling off the attributes of recycled EPS and the potential of using bio-based epoxy for glassing a surfboard instead of using polyester resins. The majority of surfboards on the market today are manufactured with polyurethane foam cores, which can be recycled but aren’t in any meaningful quantity, and these boards are made with polyester epoxies.

Prior to launching Sustainable Surf, Stewart worked at Underwriters Laboratories, a standards-setting organization serving the electronics industry. He knows from standards. And he’s quick to point out that Sustainable Surf is still a long way from developing a sustainability standard for the surf industry鈥攄oing so will be major undertaking. “We’re going to build a standard,” he says. “But first it’s a [bench]mark.”

The benchmark provides a good starting point. It was created using thorough life cycle assessment (LCA) studies, which hash out the carbon emissions and toxicity of just about every step of a board’s manufacture and its constituent parts.

By using bio-based epoxy resin (which replaces some of the petroleum ingredients with bio-based materials such as paper industry byproducts and biofuel) and recycled EPS blanks, surfboards can be made with a 40 percent smaller carbon footprint and 100 percent fewer toxic components.

Introducing the Ecoboard

A finished surfboard can be sold with the Ecoboard mark if it meets at least one of these three requirements:

- A foam blank with a minimum of 40 percent

recycled content, or at least 40 percent biological (non-petroleum) content. - A board glassed with epoxy resin containing

at least 15 percent biological content. - A wood blank (a number of board makers have

returned to surfing’s roots by making boards of lightweight woods). - Certified Ecoboards include a label with a QR

code that consumers can scan in order to learn more about the benchmark and the

board’s backstory.

But in many respects, Stewart is just hoping to nudge the surfing industry鈥攕tarting with board construction鈥攊nto the 21st century. Despite surfing’s rootsy image, the environmental impact of the petroleum-heavy tools of the trade, from boards to wetsuits, is largely ignored. “When Walmart is kicking your ass on sustainability, you know you’re [driving] on cruise control,” Stewart says of the surf industry, though he notes there are some standouts, such as Patagonia, that are making a concerted effort to lessen the sport’s impact.

The Bigger Picture

“Riding an Ecoboard is not going to save the planet,” says Stewart. But it’s a first step, he thinks, toward starting a conversation about surfing’s connections to climate change. Another trigger for those conversations鈥攖he rising sea levels that threaten to, as Stewart describes it, “swamp out surf breaks”鈥攚ill come too late.

As Sustainable Surf grows, it plans to not only mature the benchmark into a full-on standard, but also expand into wetsuits and other surf-related products. The hope is that the momentum behind and the demand for more environmentally-friendly products will grow and major surfboard manufacturers will start to use recycled EPS foam and bio-based resins.

Recycled EPS is easy to recycle and can be continuously recycled, meaning that the foam from an EPS-based board could actually be reused at the end of the board’s life. But the EPS recycling market depends on the collection of used EPS from reliable, consistent sources. To ensure that this happens, Sustainable Surf launched the program in partnership with Reef, Surfrider Foundation, and other groups to establish and promote used EPS collection boxes throughout California coastal communities. The boxes are generally located outside of surf shops and most material collected is from consumer packaging.

Waste to Waves passes the foam onto , which supplies recycled EPS blanks to some of the industry’s top board shapers.

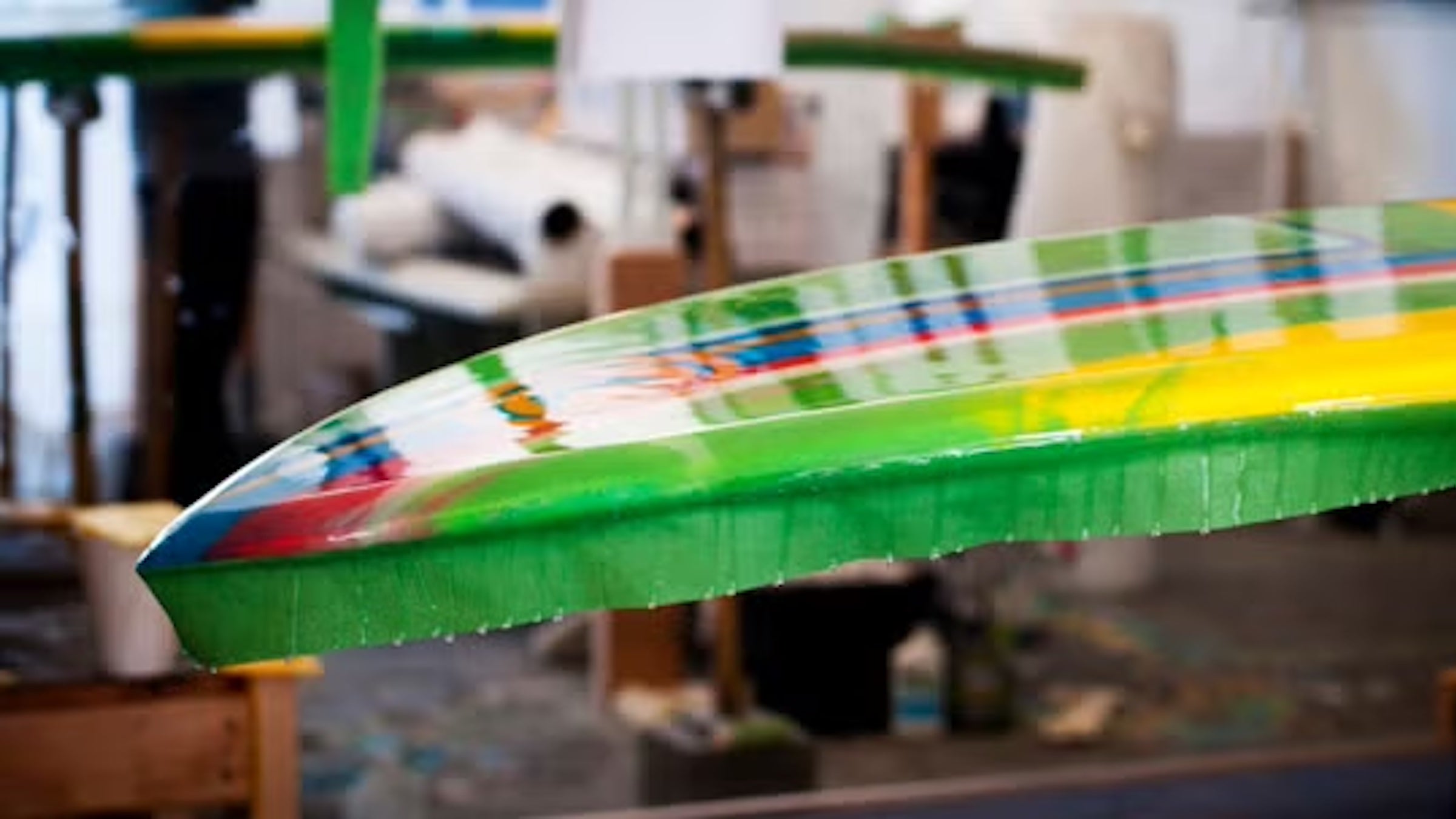

Stewart is keen to get key figures in the surf industry behind him, and a number of shapers are already starting to use EPS blanks rather than polyurethane versions because most contend that the boards are no different in the water, and the EPS boards are durable and therefore longer lasting. They tend to like epoxy resins, too, because the low- or no-VOCs means they can apply them sans noxious smells and facemasks. At the Ecoboard launch event, guests watched techs from and turn a recycled EPS blank into a surfboard using Entropy’s Super Sap epoxy.

Consumers have to ante up a bit more for an Ecoboard鈥攂ut what was $100 premium is quickly falling, and a new Ecoboard from Lost costs only $50 more than its other boards. But some of the top surfers in the world have started riding Ecoboards, which should stoke sales.

Case in point, here’s Torrey Meister making a recycled EPS board dance:

* The original post listed epoxies as also being toxic, which was an error. It has been corrected.